Quicklock Pipe Repair System

Call for Pricing

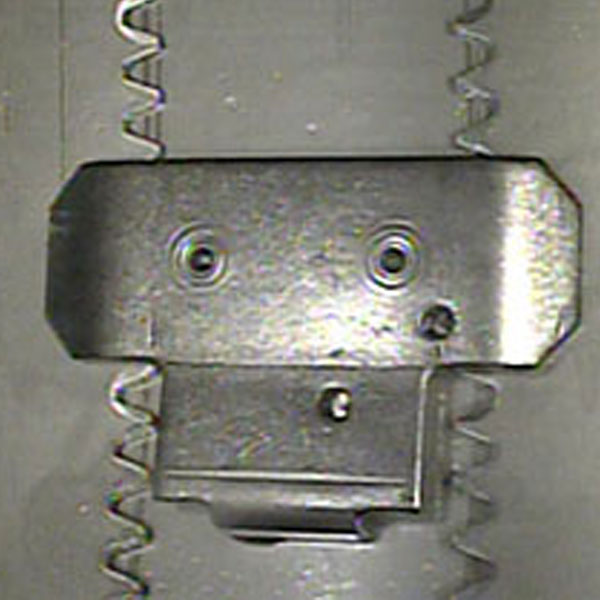

QuickLock is a strictly mechanical point repair system for the inside repair of pipes. No resin is involved. This revolutionary system consists of only (2) components: a 316L stainless steel sleeve structural body, covered by a seamless EPDM compression seal. Through the manhole the sleeve is inserted into the pipe and placed over the damaged section. Using an inflatable packer, the sleeve is then expanded and permanently locked into position. Sleeve sizes are available from 6″ to 32″ in circular pipe diameter.

- Application for:

- Municipal sewage lines

- Well and potable water piping systems

- Leaking and/or offset joints

- Root intrusion

- Holes, longitudinal & circumferential cracks

- Abandon laterals

- Restore structural integrity of pipe prior to lining